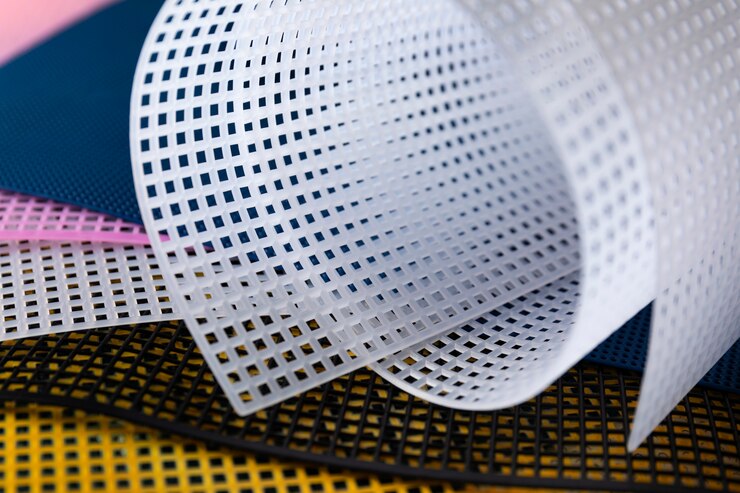

Microperforated materials are smooth materials riddled with a huge number of tiny perforations (most of which are less than one millimeter in diameter). These perforations improve the material’s acoustic properties but conceal the fact that it is riddled with miniature holes.

These materials have architectural, ventilation, and airflow benefits, and they’re often used in consumer electronics (like when creating speaker grilles or subtle device ventilation). Nonetheless, as we’ve previously mentioned, they’re mostly used for the improvement of the acoustic properties of a given material.

With that in mind and without further ado, here are some of the top advantages and disadvantages of microperforated materials.

Advantages

First, let’s tackle the advantages of using microperforated materials. In other words, let us address why these materials are used and what they’re used for.

Better acoustics

Smooth materials reflect the sound most strongly, which is why microperforated panels are so popular as a soundproofing technique. This way, you can use them in office spaces and industrial areas to keep the noise down. It will allow you to improve productivity and prevent some of the worst outcomes for the mental health of people present.

The best thing about microperforated materials is that the term itself only describes that there are perforations. In other words, there’s a wide range of materials, some of which already have decent acoustic properties which will only be made better when they’re microperforated.

Better airflow and ventilation

Micro perforations can do wonders for airflow and ventilation. Seeing as how there are these micro holes all across the panels, they can seriously contribute to the quality of airflow in the room and thermal comfort within the space.

This is especially important for crowded indoor areas like commercial, industrial, and retail spaces. Sure, they won’t eliminate the need for proper ventilation, but they will make a world of difference in the overall outcome. This is why they’re favored so strongly by commercial interior designers.

Lightweight and durable

Perforations are tiny holes, and while they are really tiny, there are so many of them that the difference in mass may be noticeable. You see, the thing is that these materials are manufactured and designed so that they’re better at their task, regardless if they’re supposed to provide better airflow, insulation, or acoustics. This means that you’ll need less of a given material to achieve the task at hand.

Cost-effective

Microperforated materials are sometimes a tad more expensive than their conventional counterparts. This means that the upfront cost of installing and using them might be a bit higher. At the same time, they’re longer-lasting, more durable, and better at what they do. This means that the dollar value you get for them tends to be superior to any of the alternatives.

Also, keep in mind that these materials are often made from recycled or sustainable materials. This means that you’re actually giving money towards an industry that’s a part of the solution, not a problem.

Disadvantages

As you may have noticed, microperforated materials aren’t exactly a common thing. Now, after we have listed all the advantages, this may puzzle you. How come they’re not more widely used if their properties are so amazing? Well, there are downsides, as well. Here are some of them.

Complex manufacturing

This part right here is the root of all the problems with microperforated materials. No, it’s not just punching a hole in a material surface; it’s about doing it in a precise and effective manner, which will not jeopardize the structure of the material but will, instead, enhance its properties.

The reason we say that this is the root of all its problems will be explained in the further sections. However, right off the top of our heads, it’s worth mentioning that the fact that it’s so complex to manufacture means that its up-front cost is substantially higher (so that it can cover the cost of manufacturing).

Limited availability

Because they’re so hard to make, these microperforated materials are limited in availability on the market. This means that you’ll have a much harder time finding them, which also means that your ability to negotiate and shop around might not be as great.

In other words, you’ll be lucky if you find a vendor who has it in their offer. This also means that unless you’re lucky enough to find a good vendor, the number of options you have might be limited quite drastically.

Installation expertise

Since these materials are limited in availability, many installers never get a chance to work with them. Those who do might have done it only a few times, which means that they’re not nearly as experienced with them as they are with some other materials.

Then, there’s a group of installers who never found it cost-effective even to try learning how to handle these materials. Why would they when there are only a few instances when they’ll actually get to work with them?

Does this mean that they’ll refuse you with an excuse that they don’t know how to do it? Of course not! They’ll just do a poor job!

Maintenance challenges

Another thing you need to understand here is that these materials require a specific approach to maintenance. They’re more complex to clean, and they could get clogged without you even noticing. That’s the tricky part. The material looks smooth, which means that it’s also likely that it will look clean (when, in reality, it will be anything but).

Still, the more difficult and impossible to clean are not one and the same thing. You’ll face a lot of maintenance challenges, but with the right practice (and cleaning solution), it shouldn’t be that hard.

Wrap up

In the end, the list of advantages and disadvantages of microperforated materials isn’t really comparable. The biggest downside is that there are fewer of these materials, but if you can find them, all your problems will be solved. Sure, they’re harder to install, but you just have to install them once, and when you learn how to clean them, the maintenance issue is never going to be a huge problem again. In return, you get so much value.

0 Comments